How Are Lab Grown Diamonds Made? The Full Process, Step by Step

Diamonds have always been admired for their brilliance, strength, and symbolism. Today, with advances in technology, it’s possible to create real diamonds above the ground rather than mining them from deep within the earth. These are called lab grown diamonds. They are identical to natural diamonds in every way — same sparkle, same durability, and same beauty — the only difference lies in how they’re formed.

Let’s take a closer look at how lab grown diamonds are made, step by step, and what makes them a popular choice for modern luxury buyers.

What Is a Lab Grown Diamond?

A lab grown diamond is a genuine diamond made of pure carbon. It has the same physical, chemical, and optical properties as a mined diamond. The main difference is that it’s created inside a controlled laboratory using technology that replicates the natural conditions of diamond formation.

Instead of taking billions of years to form underground, lab grown diamonds can be produced in a few weeks. Once created, they’re cut and polished just like mined diamonds. The end result is a flawless, high-quality gem that shines with the same brilliance.

The Two Main Methods of Creation

There are two ways to grow diamonds in a lab:

• HPHT (High Pressure High Temperature)

• CVD (Chemical Vapor Deposition)

Both methods start with a diamond “seed” — a tiny crystal that acts as the base on which carbon atoms attach and grow. Each technique then follows its own process to form a fully grown diamond.

The HPHT Diamond Growth Process

The HPHT method was the first successful way to create gem-quality diamonds. It works by recreating the same natural environment in which diamonds form inside the earth — using intense pressure and heat.

Step 1: The Diamond Seed

Every lab grown diamond starts with a small diamond seed. This seed is chosen carefully for its quality, as it determines how well the new crystal will grow.

Step 2: Placing the Seed in a Chamber

The seed is placed inside a small capsule along with pure carbon, often in the form of graphite, and a metallic catalyst made from elements like nickel or cobalt.

Step 3: Applying Heat and Pressure

The capsule is put inside a special press that can reach extreme conditions. Temperatures rise to about 1,500°C, and pressure exceeds 1.5 million pounds per square inch. Under these conditions, the carbon begins to melt.

Step 4: Diamond Growth

Once the carbon melts, it starts to bond with the diamond seed. Over several weeks, new layers of carbon build upon the seed, gradually forming a larger diamond crystal.

Step 5: Cooling and Extraction

After the diamond has reached the desired size, the chamber is cooled carefully to prevent cracks. The crystal is then removed, cleaned, and prepared for cutting.

Step 6: Cutting and Polishing

The rough diamond is cut and polished by expert craftsmen to bring out its full brilliance and sparkle. This is where its final beauty is revealed.

HPHT diamonds may sometimes have a faint yellow tint because of the metallic elements used in the process. However, with modern advancements, colorless and fancy-colored HPHT diamonds can now be produced with excellent clarity.

The CVD Diamond Growth Process

CVD, or Chemical Vapor Deposition, is a newer and more advanced technique. It provides greater control over the growth process and usually produces diamonds with exceptional clarity and fewer impurities.

Step 1: Preparing the Seed Plate

A thin diamond seed is placed inside a sealed vacuum chamber. The surface of this seed is polished so the new diamond layers can form evenly.

Step 2: Adding Carbon Gas

The chamber is filled with gases like methane and hydrogen, which serve as the carbon source.

Step 3: Heating the Chamber

Microwave or plasma energy heats the chamber to about 1,000°C. This energy breaks down the gas molecules and releases pure carbon atoms.

Step 4: Layer-by-Layer Growth

These carbon atoms begin to settle on the diamond seed, bonding together and forming new layers. Over several weeks, the diamond grows into a larger crystal.

Step 5: Finishing and Polishing

Once the desired size is achieved, the diamond is removed and cleaned. It is then cut and polished to highlight its brilliance and fire.

CVD diamonds are often purer and whiter than HPHT diamonds because the process doesn’t use metallic catalysts. They are favored for fine jewelry where clarity and precision matter most.

Enhancing the Diamonds After Growth

After the growing process, some diamonds undergo light treatments to improve their appearance. A common enhancement is HPHT color correction, which helps remove faint yellow tones and make the diamond appear colorless. Cleaning with laser or plasma can also remove small impurities trapped during growth.

These enhancements are permanent and fully disclosed, ensuring complete transparency for buyers.

How Lab Grown Diamonds Are Graded

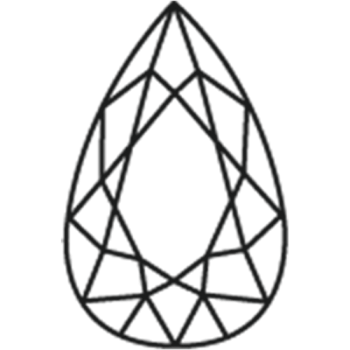

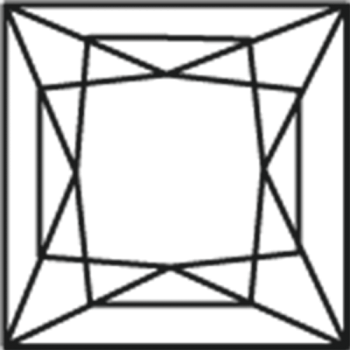

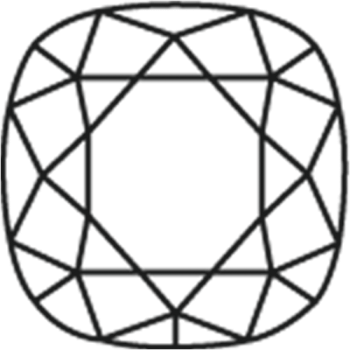

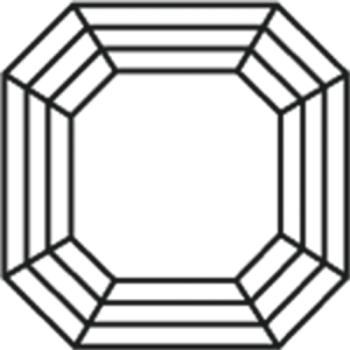

Once the diamond has been cut and polished, it’s sent to an independent gemological laboratory for grading. The grading process is exactly the same as for mined diamonds — every diamond is evaluated for the 4Cs: cut, color, clarity, and carat weight.

Reputable organizations like the GIA (Gemological Institute of America) and IGI (International Gemological Institute) issue certificates verifying a diamond’s authenticity and quality. Each stone is laser-inscribed with a small identification number that confirms it was created in a lab. The inscription is invisible to the eye and does not affect the beauty of the diamond.

Why Many Buyers Choose Lab Grown Diamonds

Many modern buyers, especially those designing engagement rings and custom jewelry, prefer lab grown diamonds for several reasons. These diamonds are created without mining, making them a more sustainable choice. The process uses significantly less land and water compared to traditional diamond mining and can be powered by renewable energy.

They are also fully traceable, meaning buyers can know exactly where their diamond came from. In addition to these benefits, lab grown diamonds typically cost less than mined diamonds of the same quality. This allows customers to choose a larger or higher-grade stone within the same budget.

Most importantly, lab grown diamonds offer peace of mind — they are beautiful, responsible, and real.

Are Lab Grown Diamonds Real?

Yes. Lab grown diamonds are 100% real. They have the same structure, durability, and sparkle as natural diamonds. Both are made of pure carbon and are the hardest known material on earth. The only difference is how they were formed — one by nature, the other by science.

Even professional gemologists need advanced equipment to distinguish between the two. To the naked eye, there is no visible difference at all.

Buying Lab Grown Diamonds in Dubai

Dubai has become a global center for luxury jewelry and bespoke design. With growing awareness about sustainability and value, lab grown diamonds are becoming a popular choice among couples and collectors.

When buying a lab grown diamond, focus on quality and certification. Make sure the stone has a valid grading report and is sourced from a trusted jeweler who is transparent about its origin. The cut should always be a top priority, as it determines how much the diamond sparkles.

At Fergus James, each lab grown diamond is handpicked for its brilliance and craftsmanship. Every piece is custom-made to match the client’s vision, ensuring that each diamond shines with unmatched beauty and precision.

Final Thoughts

The process of creating lab grown diamonds is a blend of science, precision, and artistry. Whether made using HPHT or CVD, these diamonds are the result of human innovation replicating nature’s most extraordinary work.

They offer the same timeless elegance as mined diamonds while aligning with the values of sustainability and ethical luxury. For those seeking exceptional beauty with a modern conscience, lab grown diamonds are a perfect choice.